About Engineer’s Dialogue

KnightHawk Engineering is pleased to announce the launch of Engineer’s Dialogue.

Engineer’s Dialogue will be a series of articles detailing complex topics in engineering, industry life, and multi-discipline problem solving. We will shed light on working the issues under aggressive time constraints when the cost of shut down effects the bottom line. Our aim is to provide content that is not only beneficial, but also furthers industry knowledge for all positions in the professional atmosphere, especially appreciated by engineers.

Who is KnightHawk Engineering?

KnightHawk Engineering, Inc. is a technology-based specialty engineering company that performs consulting, field services, and testing worldwide. KnightHawk’s success lies in our multi-discipline integrated systems approach to problem solving. This same approach has taken us around the world, across many industries to solve some of the most complex problems and failures companies face.

Latest Dialogue

Reader’s Archive

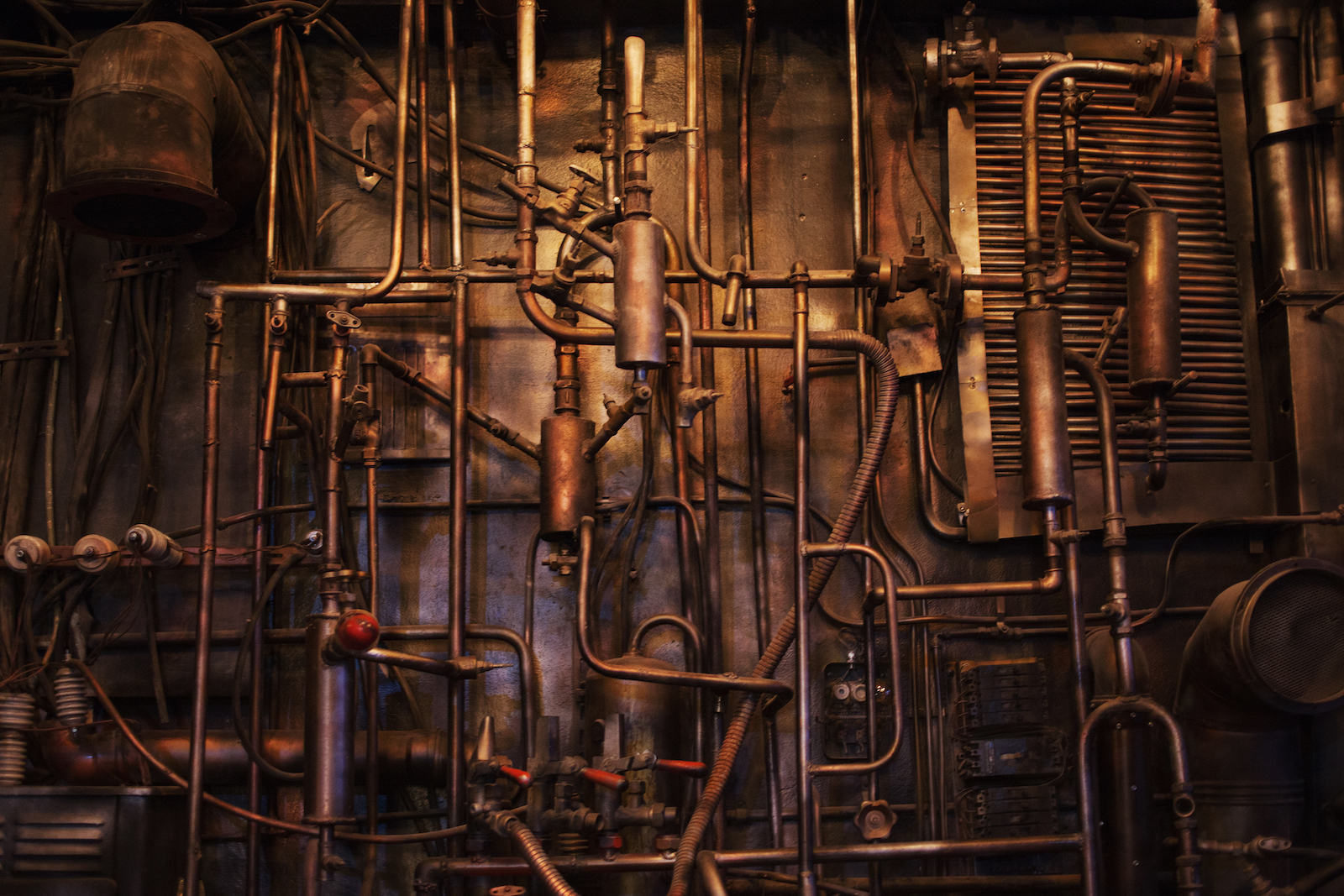

Maintaining high-energy systems

Maintaining High-Energy Systems In general, a good system will contain all the kinetic energy within the letdown device. It is 8:30 in the morning: You have just gotten out of an early meeting, and you have a sinking feeling in your gut. You’re the maintenance manager...

Finite Element Method: Thermal Walking Understood

Your Situation: Possible Pipe DamageOnce again, the operators at your production facility have approached you about a 1,600-degree Fahrenheit line where the pipe shoe has detached from the structural steel and jammed against a beam, causing a failure of the structural...

Reliability Known: The Parts That Break

Overview: Metallurgical failures can be extremely costly, resulting in replacement costs, down time, and in the worst case, injury or loss of life. Preventing as many of these failures as possible is of significant interest and importance to industry. In an ideal...

EXPERIENCE IN SOLVING MAJOR ENGINEERING – WHAT IS THE IMPACT?

Overview:Open up any engineering magazine today and you will see countless advertisements concerning engineering tools. The tools are predominately computational fluid dynamics (CFD), finite element analysis (FEA), data reduction, process analysis, rotating equipment,...

METALLURGICAL FAILURES: MICROSCOPIC EVIDENCE TO BIG INDUSTRY PROBLEMS

Overview:This article is the first installment of a new metallurgical series in Engineer’s Dialogue. Metallurgical failures can be extremely costly, resulting in replacement costs, down time, and in the worst case, injury or loss of life. Thus, preventing as many of...

TRANSIENT LOADINGS: ARE THEY THE PEAK LOADINGS?

Background:Many times, designing static and rotating equipment starts with a specifications sheet that lists performance expectations and requirements. Frequently, startup or shutdown requirements are not listed. For static equipment, this could be heat-up rates or...

IFD – INTRABODY FLOW DISTRIBUTOR FOR TRANSFER LINE HEAT EXCHANGERS (TLE’S)

Background: Transfer Line Exchangers (TLE’s) are applied widely in industry in the process of ethylene production. Its function is to rapidly quench the effluent gas from the radiant coils of ethylene cracking furnaces. The equipment, referring to Figure 1, are...

SLAG GRINDER – ENGINEERING & DESIGN

Background:Crushers and Slag grinders are often applied in Materials Handling and Gasification plants to reduce the size of quenched slag from the gasifier’s tap-hole or break clinkers from slow moving bed reactors. These clinkers are typically brittle and relatively...

RESPECT YOUR SEALS!

Background:It’s your first job as a rotating equipment engineer in a big production facility. They left you a gift: a huge noisy machine that keeps you awake at night. It has been running for years. But recently you noticed that the humming noise is turning into...